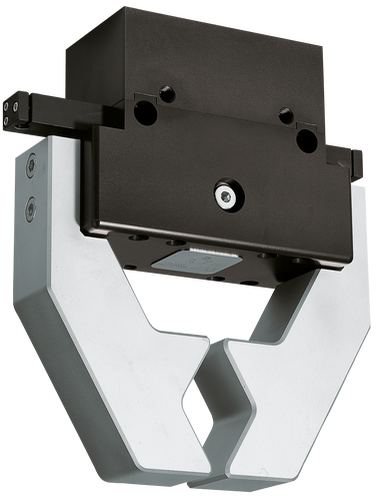

2-Jaw Parallel Grippers

Series GP1800

"The sealed"

- Suitable for use under extreme conditions

The sealed square guide guarantees process reliability even under the harshest conditions - High moment load

The overlapping square guide provides the highest possible durability for your application - Variety in the versions

Corrosion-protected, temperature-resistant or cleanroom-compatible for flexible use

Installation Size: GP1803 | |

| Order-No. | |

|---|---|

| GP1803N-B | |

| GP1803NC-B | |

| GP1803NO-B | |

Installation Size: GP1804 | |

| Order-No. | |

| GP1804N-B | |

| GP1804NC-B | |

| GP1804NO-B | |

Installation Size: GP1806 | |

| Order-No. | |

| GP1806N-B | |

| GP1806NC-B | |

| GP1806NO-B | |

Installation Size: GP1808 | |

| Order-No. | |

| GP1808N-B | |

| GP1808NC-B | |

| GP1808NO-B | |

Installation Size: GP1810 | |

| Order-No. | |

| GP1810N-B | |

| GP1810NC-B | |

| GP1810NO-B | |

Installation Size: GP1812 | |

| Order-No. | |

| GP1812N-B | |

| GP1812NC-B | |

| GP1812NO-B | |

Installation Size: GP1816 | |

| Order-No. | |

| GP1816N-B | |

| GP1816NC-B | |

| GP1816NO-B | |

Installation Size: GP1820 | |

| Order-No. | |

| GP1820N-B | |

| GP1820NC-B | |

| GP1820NO-B | |

Installation Size: GP1830 | |

| Order-No. | |

| GP1830N-B | |

| GP1830NC-B | |

| GP1830NO-B | |

| Order-No. | |

| GP1800 Introduction | |

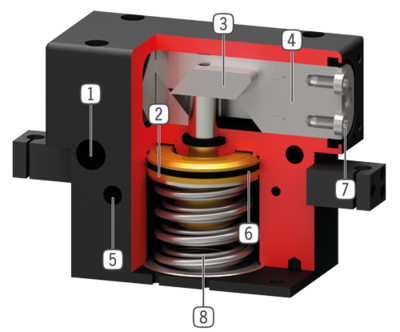

- Mounting and positioning

mounting possible from several sides for versatile positioning - Permanent magnet

installed in piston area - Wedge hook mechanism

synchronized the movement of the gripper jaws high force transfer - Sealed and precise square guide

high forces and moments capacity - Energy supply

possible from several sides - Drive

double-acting pneumatic cylinder - Removable centering sleeves

quick and cost-effective gripper finger positioning - Integrated gripping force safety device

optional via intergrated spring (C and O Models)